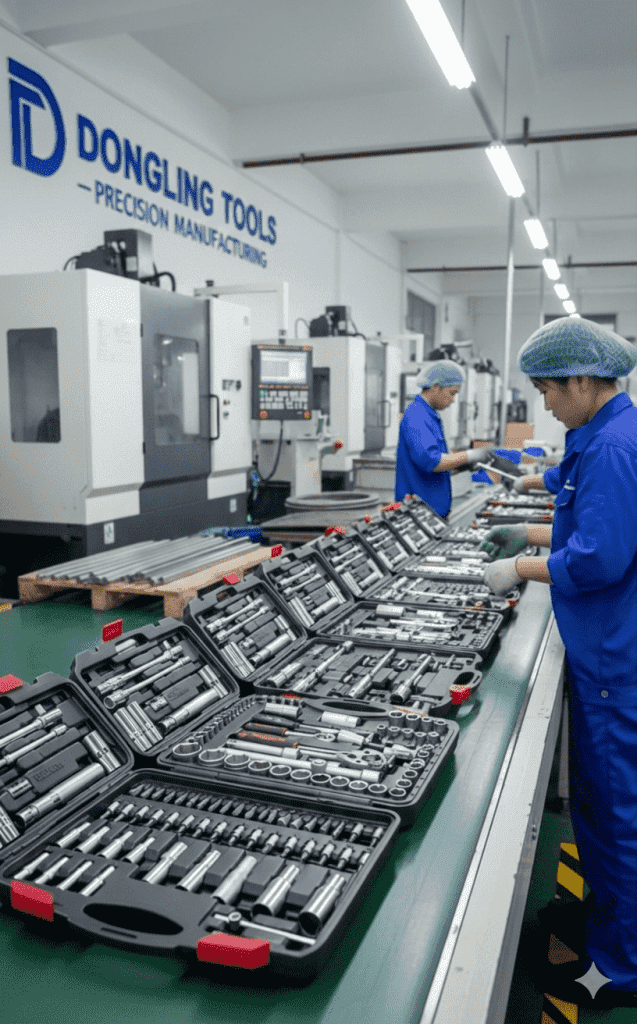

Inside the production processes of a leading OEM partner building the tools professionals trust.

When a professional mechanic or a serious DIYer reaches into their toolbox, they aren’t just grabbing a piece of metal; they are reaching for a promise of reliability. A rounded bolt or a cracked socket in a tight engine bay isn’t just an inconvenience-it’s lost time and money.

For tool brands, maintaining that promise is everything.

As a leading Original Equipment Manufacturer (OEM) factory, Dongling Tools understands that our reputation is the foundation of your brand’s reputation. We don’t just manufacture combination socket sets; we engineer confidence.

Today, we’re pulling back the curtain on the production expertise that makes Dongling Tools the silent powerhouse behind many of the market’s top-tier tool sets.

1. The Foundation of Strength

At Dongling, we utilize premium-grade Chrome Vanadium (Cr-V) steel and, for specialized applications, S2 steel. But sourcing good steel is only step one. The magic happens in the heat treatment.

Our proprietary multi-stage heat treatment process is scientifically balanced. If a socket is too hard, it becomes brittle and shatters under impact. If it’s too soft, it deforms and rounds off fasteners. We achieve the precise Rockwell Hardness (HRC) sweet spot, ensuring maximum torque transmission without compromising structural integrity.

2. Precision Cold Forging: The Perfect Fit

In the world of professional tools, “close enough” is failure. A 13mm socket must be precisely 13mm, every single time, across a production run of thousands.

Dongling Tools utilizes advanced cold forging technology. Unlike machining, which cuts away material and interrupts the steel’s grain structure, cold forging compresses the steel into shape. This aligns the grain flow with the geometry of the socket, significantly increasing its inherent strength.

3. The Finish Line: Durability Meets Aesthetics

A socket set needs to perform under the hood of a greasy 10-year-old truck and look pristine on a retail shelf. Our finishing processes are designed for both extreme durability and visual appeal.

We offer highly specialized surface treatments, from mirror-polished triple chrome plating for superior corrosion resistance to rugged black phosphate finishes for impact-rated tools. Our in-house salt spray testing ensures that our finishes far exceed industry standards for rust prevention, ensuring the tools look professional even after years of hard use.

4. The OEM Advantage: Consistency at Scale

Manufacturing ten perfect sockets is easy. Manufacturing ten thousand perfect sockets requires systems, discipline, and rigorous Quality Control (QC).

For Dongling partners, scalability is our greatest asset. Dongling Tools’ production lines are equipped with automated inspection gauges that verify dimensional accuracy in real-time. We conduct destructive torque testing on random samples from every batch to ensure they are manufactured for the standards.

When you partner with Dongling as your OEM, you aren’t just buying inventory; you are buying consistency that protects your brand value.

The Dongling Commitment

A combination socket set is one of the most essential items in any toolkit. It must be versatile, durable, and precise.

At Dongling Tools, we combine decades of manufacturing heritage with modern engineering to deliver products that meet the highest professional demands. We are proud to be the manufacturing engine that powers leading tool brands around the world.

Are you looking for an OEM partner that prioritizes precision as much as you do? Contact Dongling Tools today to discuss your next product line.